As a part of on-going energy efficiency efforts in Balboa Park, many organizations have been upgrading lighting in their buildings to efficient LED bulbs. In July, staff at the San Diego Natural History Museum retrofitted 800 LED light bulbs using a rebate from San Diego Gas & Electric. We sat down with Michael Field, Director of Experience Design, to talk about his experience upgrading the museum with LED bulbs.

Where throughout the museum are you upgrading to LEDs?

All of the exhibit areas have been running LED lights for years. We were inspired to take action “back of house” after getting the results of an energy study showing the percentage of our electricity usage dedicated to lighting. The priority for LED retrofits was to address our 24/7 lighting and areas with large banks of 48” fluorescent lights such as classrooms, the Library, and large collection areas. Many of our new exhibits are being installed in general public areas of the Museum so we have been budgeting and installing a variety of LED lights, including complete fixture replacement in some areas with each new exhibit project.

(The Museum) is currently at 60% LED lights, with the 800 new LEDs installed. We have a grand total of 4,000 +lights operating in the building. This brings up another energy savings strategy; reducing the total number of lights burning. The newer LEDs put out almost twice the light levels over many traditional lamps and we are starting to reduce the number of lights operating throughout the entire museum with a target of 25%. We use a light meter to check the light levels in each area based on the intended use of that area and can then remove a lamp if it’s too bright. Ceiling height has a big impact on the brightness of a light. Moving a light by 6 feet can lower or raise the light levels on your light meter by 50%.

What is the process of upgrading to LEDs like?

We needed some serious outside help to pull off switching out 800 lamps in a single batch. Just counting to 800 is exhausting. We partnered with Regency Lighting, ABM (American Building Maintenance), Sylvania and SDG&E. I met with Gene LeDuff, Pacific Region Executive from Sylvania and Scott Clark, Lighting Specialist with Regency Lighting in Regency’s new Kearny Mesa facility to examine the latest LED lamp offerings from Sylvania. We had a great time shinning white lights on a white wall and talking about what I’m looking for in Museum lighting and what California Compliant lighting requirements we might be seeing in the future. Gene just returned from a trip to Sacramento working directly with the folks who are writing those energy savings policies.

I picked out some fantastic mix-n-match lamps that can be used for both our back of house lighting and our exhibit lighting. Scott Clark then introduced me to Paul Venisse, Senior Account Executive at ABM to purchase those lights and come up with a plan to get all 800 lights installed – including the impossible to reach ones. Price per light purchased and installed cost less than a pumpkin scone and caramel latte from a global chain of local corner coffee shops.

Regency Lighting works directly with SDG&E to take care of submitting the application to SDG&E for the rebate. We used the rebate money to pay ABM for the lamp installation. My only direct interaction with SDG&E was to meet the SDG&E inspector at the Museum to verify the work was performed as described. I took full advantage of my time with the inspector to ask all manner of lighting related questions. I see interactions with building inspectors as a big opportunity to ask questions and learn from the experts.

What advice would you have for someone upgrading to LEDs?

I think most large scale LED retrofits get complaints because the lamps that were purchased and installed are the wrong color temperature and appear too harsh.

You need to start buying and testing potential LED lights in a variety of spaces inside your own building to see how they look and perform before jumping into a big retrofit project. You’ll want to give the color temperature some serious thought and look at the brightness of the lamps to make sure they are appropriate for the intended use of the room. Use your light meter and consult one of the many resources online to get a target light levels based on the task at hand. Is it a hallway or research laboratory? Most buildings have a variety of light bulb sizes so you’ll need a “family of lights” with the same specs from a single manufacturer in order to have consistent lighting in your building.

Many people are very sensitive to the quality of light in their personal work areas, so you’ll want to take the time to test your lights in small office settings with people you will be working with every day, long after the lights are installed. You’ll also want to let your fellow workers know that this LED lighting upgrade is happening well in advance and that they are welcome to come by to examine your sample lights. No surprises.

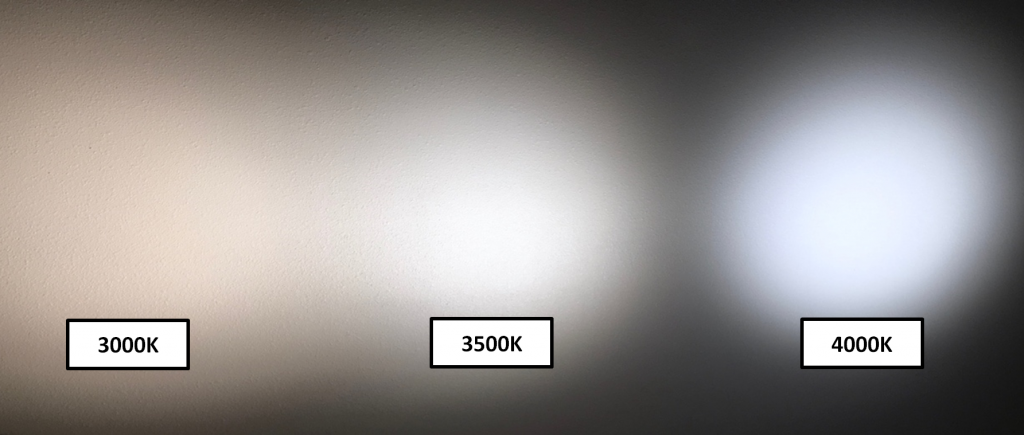

For example, we pointed the test lights on this white wall at Regency Lighting to look at color temperature and beam spread of different lamps. Color temperature for lights is measured in Kelvins and is shown as a number with a K at the end. If you have lots of natural light, 4000K is a great option. However, you might get some negative feedback when installed in a small office without natural light. To my eye the 3000K lamp on the left looks dirty; the 3500K in the middle looks perfect and it makes me wonder why they bother to manufacture the other two lights. The 4000K on the right looks cool blue. I wanted the white wall to look white, so we went with 3500K. If you have lots of natural light 4000K is a great option, but you might get some negative feedback when installed in a small office without natural light.

Here’s an extraordinary photo of old school fluorescent 3000K lamps on the left and 4000K LED test lights on the right. You can see that the 3000K lights on the left have a distinct warm cast when installed in an area with abundant natural light. In a gallery with very few windows 3000K looks just dandy and in ancient times (10+ years ago) 3000K track lighting was the only game in town for first class exhibit lighting.

In this photo we are comparing two LED PAR38 lamps both rated with the same color temperature at 3000K printed on the box. This is fantastic example of why you need to buy and test your lights with your own eyes. I should take a minute to mention color rendering. Color rendering is the ability of the lamp to render a full spectrum of rich colors. it’s a different measurement than color temperature. In the early days, energy efficient lighting scored rather poorly on the color rendering index. Primitive LED designs filtered out the blue end of the color spectrum to “enhance” the warm colors resulting a completely anemic gallery. These days warm colors are added in front of the LED module. If you look at the business end of a better quality LED (before it’s installed) you’ll see a yellow phosphor thing-a-ma-jig installed in front of the LED module to improve the quality of the light. I used to be obsessed with finding the highest Color Rendering Index (CRI) numbers available. These days most better quality LEDs do a dandy job rendering colors. Rather than obsess over numbers printed on a box I’ve taken to comparing a pair of lamps by alternating between them as they shine on a fan deck of paint colors focusing on the orange and magenta colors in a dark room. If you toggle between two lights a few times you’ll have a winner and a loser in less than three minutes. Losers get to light the bench in the corner of the room.

What benefits have you seen from switching to LEDs?

The LED lights we started using this year are the best lights we have ever installed based on overall quality, price and performance. The areas with the new lights look better than new. Only negative is that you can see we are running behind on our touch-up painting.

Apart from the dramatic energy savings… you save even more money on reduced maintenance costs.

Setting the financial and performance benefits aside, switching from obsolete lamps to LED lamps and then reducing their hours of operation is one of the easiest ways to achieve a significant reduction in your carbon foot print. I think we all need to cut our energy use in half both at home and at work. My wife and I ditched a full power strip worth of electronics by getting rid of the flat screen TV in the living room. We replaced the TV with a Native American Hopi pot in the living room and a pair of nice humming bird feeders outside.

Do you have any additional comments about the LED project?

We achieved LEED certification in 2009 and the lights that met those LEED requirements are the ones we are frantically trying to replace today. That’s the wonderful thing about lighting in large buildings – you will never actually be finished and the lights keep getting better and better!